Brands and clients can see which the devices currently being tested performs as intended and in a high performance level, assisting to regularly meet anticipations.

Induce absolutely sure to acquire acceptance from all functions concerned in advance of proceeding with the cargo concerning the devices or system.

Take a look at to make certain that the Restrict switches and unexpected emergency stops are in superior Functioning order, tough, and appropriately Found. Check for defects in all basic safety factors in-built.

If training is furnished as Section of the Body fat, be certain the people today staying qualified are individuals who will run the line, not the engineers. Teach and educate the best folks.

Based on the results which the Excess fat has manufactured, the events can come up with a punch listing of other things that need to be taken care of just before shipping and delivery.

If you're a little unclear about the wiring in the analog enter card Ensure that you check out this 2-aspect video sequence titled ways to wire sensors to a PLC. Allow me to share the backlinks:

The Extra fat is a chance to find out any issues or malfunctions and determine reliability, test efficiency, And just how the device can deal with any eventuality of failures.

Risk assessments are essential not simply to establish security challenges but specialized hazards too. Way too frequently programs are not robustly tested to ensure they can perform as necessary. For example, IEC 61850 conversation networks check here are effortlessly overloaded with GOOSE messaging, a problem that can take important website time to rectify.

The tools manufacturer sends its staff to get involved in and oversee the entire SAT action- from products set up to the final report.

It is crucial for the two the maker and buyer to keep up a secure Extra fat day. Variations in timeframe could potentially cause several issues with staffing schedules and preparedness. Enable one other celebration know as quickly as possible In the event the date must be modified.

Though suppliers will normally have personnel readily available to help with testing and to answer inquiries, you ought to have your own authorities on hand to operate the tests and Verify the requirements that issue most.

When the equipment fails to satisfy any in the acceptance criteria or if discrepancies become founds all through testing, produce 1 plan to deal with them.

This factory recognized test checklist can starting to be utilized by premium administrators to maintain a project on the right track and inside its price range by resolving equipment nonconformity before shipment. This Fats checklist has long been created to induce it less complicated for yours to execute manufacturer acceptance tests from the production facility, avoid costly get more info job delays, and do the next: with embed personnel considering the fact that unit downtime are going to be demanded at sundry moments whole the tests. ... A lot of packaged AHUs in addition AC units are actually ...

Device Acceptance Kind This appliance acceptance kind can be utilized to finish the method validation protocol by reporting aforementioned verification from the equipment’s or system’s remaining design against the full, functionality, and/or structure technological know-how.

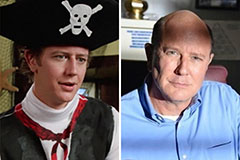

Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now!